Onshore high-voltage substations – often called switchyards, switching stations, or grid stations – are the critical hubs that keep electricity flowing to power our world, from renewable energy projects to data centers driving AI and cloud computing. Installing or upgrading these vital facilities requires precision, speed, and reliability. Our pre-terminated HV cables are designed to meet these challenges, revolutionising substation projects with unmatched advantages. Here’s how they transform onshore power systems and why Reynard is your go-to partner.

What Are Pre-terminated HV Cables?

Pre-terminated high-voltage cables are factory-assembled with ready-to-use terminations – plug-in connectors, stress cones, or joints – designed for seamless integration into substations operating at voltages above 36 kv. Unlike traditional cables that require time-intensive on-site termination, our cables are pre-tested and customised to your project’s specifications, built to connect with substation components such as circuit breakers, transformers, or busbars. Produced in our state-of-the-art facility, they are crafted to enhance onshore grids, also referred to as transmission yards or interconnection stations, with confidence.

The Benefits of Pre-terminated Cables for Onshore Substations

1. Accelerate Installation Timelines

Substations, often called distribution yards, are the backbone of power delivery, and any downtime is costly. On-site termination entails complex tasks—stripping cables, layering insulation, and assembling joints—that can delay projects by days across a substation’s expansive layout. Preterminated cables remove these obstacles, providing plug-and-play connections tailored for substation equipment.

Whether you’re building a 230 kV substation for a hyperscale data center or upgrading one for wind power, our cables can significantly cut installation times. This efficiency ensures that power flows to critical infrastructure on schedule. At Reynard, our factory delivers cables to order, arriving ready to integrate, so your grid station powers up without delay.

2. Maximize Reliability with Factory Precision

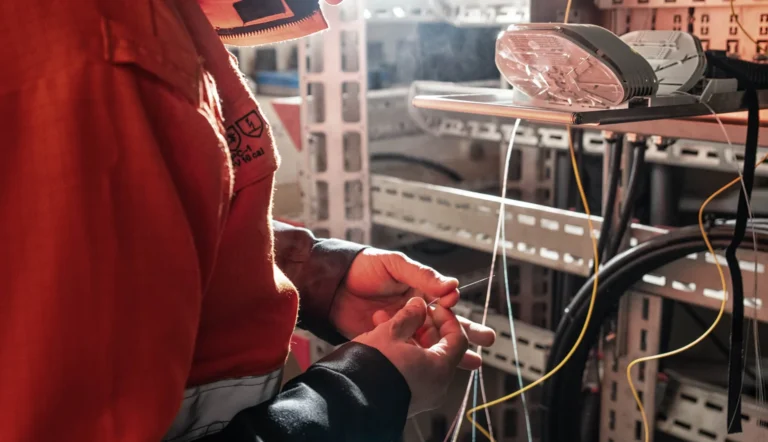

Substations face intense demands—managing high voltages, variable loads, and outdoor conditions. A faulty connection can cause partial discharge, insulation failure, or outages, disrupting everything from renewable grids to industrial operations. On-site termination in open-air switching stations risks inconsistencies, as dust, wind, or human error can compromise quality. Preterminated cables solve this with factory-controlled precision.

Using automated tools and strict standards, we assemble terminations to meet rigorous specs. Every cable is tested before it ships, ensuring secure connections throughout your substation. Whether powering data centers with zero downtime or stabilising renewable energy, Reynard delivers reliability you can count on.

3. Prioritize Safety in High-Voltage Environments

Safety is critical in substations, where high voltages and outdoor exposure heighten risks. On-site termination exposes jointers to electrical hazards, heavy equipment, and weather challenges. Preterminated cables shift these tasks to our factory, reducing field work to safe, simple connections.

In onshore substations, often referred to as transmission yards, plug-in terminations minimise exposure to live systems, reducing arc-flash risks as workers navigate among towers and busbars. Our cables comply with all current safety standards, safeguarding teams and ensuring that your interconnection station powers a variety of industries securely, from technology campuses to solar farms.

4. Seamlessly Connect with Substation Systems

Today’s substations rely on advanced technology – digital monitoring, modular busbars, or eco-friendly components like SF6-free breakers. Our pre-terminated cables are designed to match, with terminations like dry-type connectors or pre-molded plugs that integrate flawlessly. Whether linking transformers for a grid expansion or breakers for a data center, we ensure perfect compatibility.

For smart substations, we can embed sensors in terminations, supporting real-time monitoring to keep renewable grids or mission-critical facilities running smoothly. Reynard customises cables for leading equipment brands like Siemens, ABB, or GE, streamlining your installation or upgrade with precision.

5. Simplify Logistics Across Complex Sites

Substations, or distribution yards, span acres, with cables connecting towers, transformers, and control houses. Shipping termination materials to these sites adds logistical complexity. Preterminated cables arrive as complete units and are ready to install.

This simplicity scales for major projects, such as constructing a substation for a data center or upgrading one for regional power. Reynard’s factory produces customised batches on your timeline, ensuring cables arrive at your substation when needed, hassle-free.

Why Choose Reynard’s Pre-terminated Cables?

Our decades as HV jointers and testers give us unmatched insight into substation challenges. We’ve harnessed that expertise in our cutting-edge factory, producing pre-terminated cables that deliver precision, reliability, efficiency, and safety.

Factory-crafted terminations ensure uncompromising quality. Pre-tested cables guarantee secure substation performance. Plug-and-play designs expedite your timeline.Solutions that safeguard workers and infrastructure.

Whether you’re installing a substation for a data center’s power supply, upgrading one for industrial growth, or enhancing reliability for renewable energy, Reynard’s preterminated cables are engineered to optimise your onshore project.

Partner with Reynard

As power demands surge, pre-terminated HV cables are redefining onshore substation projects. At Reynard, we are ready to partner with the best, bringing secure, efficient high-voltage solutions to the table. Contact us.

Pre-terminated high-voltage cables are factory-assembled with ready-to-use terminations including plug-in connectors, stress cones, or joints designed for seamless integration into substations operating at voltages above 36 kV. Unlike traditional cables requiring time-intensive on-site termination, our pre-terminated cables arrive fully tested and customized to your project specifications, ready to connect with circuit breakers, transformers, busbars, and other substation components.

Pre-terminated cables are ideal for a wide range of substation applications, including:

– New 230 kV substations for hyperscale data centers

– Renewable energy integration projects for wind and solar farms

– Grid expansion and reliability upgrades

– Industrial power infrastructure development

– Mission-critical facilities requiring minimal downtime

– Smart grid and digital substation implementations

– Switchyards and transmission yards with tight timeline requirements

Pre-terminated cables eliminate the need for complex on-site termination work that typically includes stripping cables, layering insulation, and assembling joints—tasks that can delay projects by days. Our plug-and-play connections are specifically tailored for substation equipment, allowing for immediate installation upon delivery. This efficiency ensures that power flows to critical infrastructure on schedule, whether you’re building a new substation or upgrading existing facilities.

Substations face intense demands—managing high voltages, variable loads, and outdoor conditions. On-site termination in open-air switching stations risks inconsistencies due to dust, wind, or human error. Our pre-terminated cables are assembled using automated tools in controlled factory environments, adhering to strict quality standards. Every cable undergoes comprehensive testing before shipping, ensuring secure connections that prevent partial discharge, insulation failure, and outages that could disrupt operations from renewable grids to data centers.

Safety is critical in substations where high voltages and outdoor exposure heighten risks. Our pre-terminated cables shift complex termination tasks from the field to our factory, reducing on-site work to safe, simple connections. Plug-in terminations minimize exposure to live systems, reducing arc-flash risks as workers navigate among towers and busbars. All our cables comply with current safety standards, safeguarding teams while ensuring your interconnection station powers various industries securely.

Absolutely. Our pre-terminated cables are designed to match advanced substation technologies, including digital monitoring systems, modular busbars, and eco-friendly components like SF6-free breakers. We offer terminations such as dry-type connectors and pre-molded plugs that integrate flawlessly with equipment from leading manufacturers like Siemens, ABB, and GE. For smart substations, we can embed sensors in terminations to support real-time monitoring, keeping renewable grids and mission-critical facilities running smoothly.

Substations typically span acres, with cables connecting various components including towers, transformers, and control houses. Shipping individual termination materials to these sites adds logistical complexity. Our pre-terminated cables arrive as complete units ready to install, simplifying material management and reducing on-site inventory requirements. We produce customized batches on your timeline, ensuring cables arrive at your substation exactly when needed.